At Ceratem, we manufacture products based on cordierite–mullite (Al₂O₃–SiO₂), designed to withstand temperatures of up to 1,400 °C and provide exceptional resistance to thermal shock. Thanks to their low thermal expansion and structural stability, these materials are ideal for industrial furnace applications, electrical insulation, support trays, and various demanding solutions in high-temperature and high-wear environments.

At Ceratem, we manufacture products based on cordierite–mullite (Al₂O₃–SiO₂), designed to withstand temperatures of up to 1,400 °C and provide exceptional resistance to thermal shock. Thanks to their low thermal expansion and structural stability, these materials are ideal for industrial furnace applications, electrical insulation, support trays, and various demanding solutions in high-temperature and high-wear environments.

Cordierite and mullite are minerals widely used in the production of kiln shelves and other structural elements in thermal equipment. While cordierite is naturally occurring and commonly used in industry, mullite is a material rarely found in nature and typically produced synthetically as a high-purity powder. Their combination results in materials with high mechanical strength and durability—essential characteristics for applications requiring thermal stability and corrosion resistance.

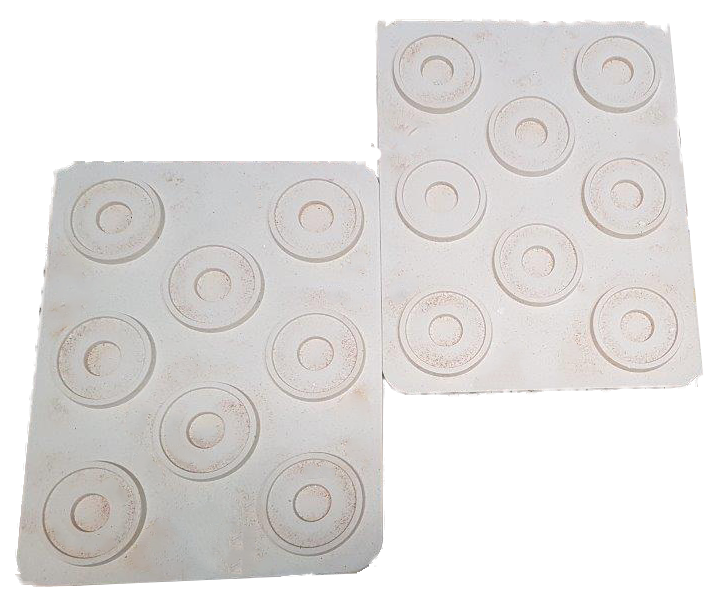

Shelves and components made from a blend of cordierite and mullite powders are shaped and sintered to ensure a homogeneous and robust structure. These materials are highly resistant, rigid, and capable of supporting heavy mechanical loads in high-temperature environments. However, proper handling and drying before use are essential to prevent cracking or air bubbles during thermal exposure.

Industrial applications of cordierite–mullite include use in high-temperature furnaces, heaters, electrical insulation, and support trays for manufacturing processes. Their resistance to thermal shock and chemical stability make them a reliable choice for industries that require high-performance ceramic materials.

At Ceratem, we develop optimized cordierite–mullite solutions to ensure maximum performance in demanding industrial applications.

Contact us to learn more about our options and find the most suitable solution for your industry.