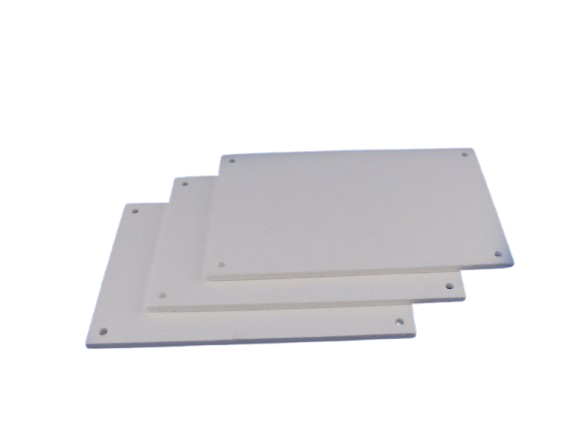

At Ceratem, we manufacture high-performance components from alumina oxide (Al₂O₃) and zirconium oxide (ZrO₂), two essential materials in engineering technical ceramics.

Alumina oxide is characterized by its hardness, thermal stability and chemical resistance, making it an ideal material for applications requiring high wear resistance, electrical insulation and compatibility with corrosive environments. Zirconium oxide is noted for its exceptional fracture toughness and high thermal expansion, making it particularly suitable for ceramic-metal bonding and applications subject to extreme mechanical stress.

These materials offer superior wear and abrasion resistance, as well as high chemical stability against aggressive agents. Their excellent performance in extreme temperatures and their ability to seamlessly bond ceramics and metal make them an advanced solution for multiple industries.

The applications of these materials cover sectors such as the metallurgical industry, where they are used in the manufacture of refractories and high-wear components, and the medical sector, in the development of implants and bioceramics. In the aerospace sector, they are essential for the manufacture of high-temperature structural components, while in the electronics industry they are used as insulators and ceramic supports.

At Ceratem, we combine cutting-edge technology and rigorous quality control to develop advanced ceramic solutions that optimize the performance of each application. Our commitment is to offer innovative materials tailored to the specific needs of each industry. For more information about our solutions, please contact us.